Tom McFadden

F U R N I T U R E

P.O. Box 162 - Philo, CA 95466 - (707) 895-3606

www.mcfaddenfurniture.com - tamcfad@pacific.net

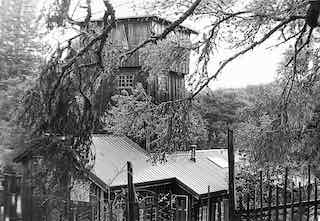

Water Tower

|

We tore down an old water tower on the nearby Day Ranch and used a lot of it in building ours. We built a "gin pole" derrick to do it. It was made

from two smaller redwoods cut in our woods. The larger one, a 35 foot post with one end on the ground, was held upright by guy wires in three directions.

The "boom" was the same length but its' position on the vertical made it have the needed reach. The weight of the boom took the place of a third guy wire

in holding the post upright. My brother John came to help set the derrick up - he had experience doing such things when he worked for the circus.

John also knew how to braid rope ends and loops, and he did that for us.

|

|

Building our tower we used the derrick to lift beams into place and to lift tall sections of scaffolding from the first to the second floor. Siding, insulation, window glass and other stuff was lifted on a carriage that we built to do that. I found a rolling scaffold someplace and I would lift the carriage in place and let it hang there will I rolled the scaffold up to it and then took stuff off of it and put it in place. |

|

It took both of us to do this. I would attach a beam or a load of siding to the chain and hook that came down from the boom. That rope ran

through a block, through another block at the top of the boom, down and back again, then over to the top of the post and through a block there

and down to the bottom of the post and through a snatch block. (A block that opens so you can get the rope out of it.) I would attach the rope to the

back of the pickup and Peggy would drive forward a set distance, stop the truck and set the brake. The load would be lifted as she drove. She would walk back

to the derrick where I had would have gotten the rope out of the snatch block and secured it to a pipe that went through the post.

|